Your cart is currently empty!

China high quality 1000W 1500W 2000W 3000W 4 in 1 Laser Welder Portable Handheld Fiber Laser Welding Machine for Metal Iro Stainless Steel Aluminum Copper Brass with Factory Price air compressor oil

China High Quality Laser Welding Machine for Metal Iro Stainless Steel Aluminum Copper Brass

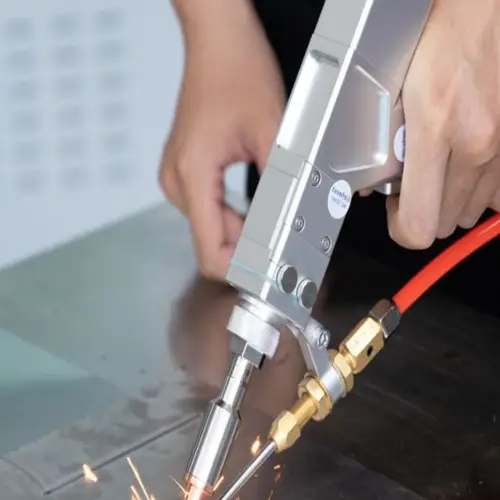

Introducing our high-quality laser welding machine that is perfect for welding various metals such as iron, stainless steel, aluminum, copper, and brass. This portable handheld fiber laser welding machine is equipped with 1000W, 1500W, 2000W, or 3000W power options to suit your specific welding needs. With its compact design and factory price, it offers convenience and affordability for both small-scale and large-scale metal welding projects.

Product Description

Our Smart HWE Series 4 in 1 Handheld Fiber Laser Welding and Cleaning Machine is the ultimate solution for your welding needs. Say goodbye to surface rust, paint, and oil dirt that hinder your welding process. This machine combines laser welding and cleaning functions, saving you time and effort in preparing the metal surfaces for welding. It eliminates the need for chemical cleaning, which can potentially damage raw materials, and manual grinding that often falls short in achieving a clean surface.

Unlike independent laser cleaning machines which can be expensive and less commonly used, our Smart HWE offers the same price as a laser welding machine but with added cleaning capabilities. It’s a cost-effective choice that maximizes your investment.

Our Advantages

- Fast switching: One machine with multiple functions

- For workshop: One machine can do all the work, saving space and cost

- For large production factory: Modify capacity allocation at any time, no more idle machines

- Laser welding is simple in operation, low in consumption, and long in service life

- Safer and more environmentally friendly

Detailed Photos

Product Parameters

| MODEL | SMART-HWE | |

|---|---|---|

| Laser type | Fiber | |

| Wavelength | 1080nm | |

| Power | 1.5KW/2KW/3KW | |

| Frequency | 20-500Hz | |

With over [number of years] years of experience, our company is a trusted supplier of various industrial products. In addition to our laser welding machines, we offer a wide range of high-quality products such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in providing products that meet the highest standards of quality and durability.

At [Company Name], customer satisfaction is our top priority. We offer competitive prices and ensure that our products are delivered with exceptional service and support. We welcome customization based on your specific requirements, whether it’s modifying existing designs or producing products from drawings and samples. Our dedicated team is ready to assist you throughout the entire process.

Frequently Asked Questions

-

Q: What is the packaging method for the laser welding machine?

A: Our laser welding machines are carefully packaged with a three-layer protection system. The outer layer is a wooden craft case to ensure the machine’s safety during transportation. The middle layer is foam, providing cushioning to prevent any shaking or impact. The inner layer consists of a thickening plastic bag for waterproof protection.

-

Q: Will the laser welding machine be damaged during transportation?

A: We have taken all necessary measures to ensure the safe transportation of our machines. Our packaging is designed to withstand all potential damage factors. Moreover, our shipping agents have extensive experience in handling delicate machinery, and we have successfully delivered our products to 180 countries worldwide. Therefore, you can be confident that you will receive your laser welding machine in good condition.

-

Q: How do I install and operate the laser welding machine?

A: Our technicians have already installed the machine before shipping. For any small parts that may require installation, we provide detailed training videos and user manuals along with the machine. Around 95% of our customers are able to learn and operate the machine themselves with the provided resources.

-

Q: What should I do if the laser welding machine malfunctions?

A: In the event of any malfunction, please contact us immediately and refrain from attempting to fix the machine yourself or seeking help from unauthorized personnel. Our team will respond within 24 hours to address the issue and provide a quick solution.

-

Q: How do I get more information or place an order?

A: For more information on our laser welding machines or to place an order, please feel free to contact us at [contact information]. Our team at [Company Name] is ready to assist you and provide additional details on our high-quality products, competitive prices, and exceptional services. Don’t hesitate to reach out to us!

Need more information? Contact us today at [contact information] and discover how [Company Name] can meet your industrial product needs!

Performance Characteristics of Laser Welding Machine

Laser welding machine is a high-tech equipment that uses laser technology to weld metals. It has many performance characteristics that make it stand out in the welding industry:

- Precise Welding: Laser welding machine uses a focused laser beam to create a precise and accurate weld, making it ideal for intricate welding jobs.

- High Speed: The laser welding machine has a high welding speed, which reduces the welding time and increases production efficiency.

- Non-Contact Welding: Laser welding machine uses a non-contact welding process, which reduces the risk of contamination and minimizes the damage to the material.

- Low Heat Input: Laser welding machine has a low heat input, which reduces the heat-affected zone and minimizes the distortion of the material.

- Wide Range of Material Compatibility: Laser welding machine can weld a wide range of materials, including metals, plastics, ceramics, and more.

Types and Characteristics of Laser Welding Machine

There are several types of laser welding machines available in the market, including:

- CO2 Laser Welding Machine: It is suitable for welding thick materials and has good welding depth.

- Fiber Laser Welding Machine: It is suitable for welding thin materials and has high welding speed.

- YAG Laser Welding Machine: It is suitable for welding small and precise parts.

The characteristics of laser welding machines vary depending on the type and model. However, some common characteristics include:

- High Welding Speed: Laser welding machines have a high welding speed, which reduces the welding time and increases production efficiency.

- High Precision: Laser welding machines have a high precision, which ensures accurate and consistent welding results.

- Non-Contact Welding: Laser welding machines use a non-contact welding process, which reduces the risk of contamination and minimizes the damage to the material.

- Wide Range of Material Compatibility: Laser welding machines can weld a wide range of materials, including metals, plastics, ceramics, and more.

Advantages of Laser Welding Machine Made of Different Materials

The advantages of laser welding machine made of different materials are:

- Metal: Laser welding machine is suitable for welding various types of metals, including stainless steel, aluminum, and titanium. It provides high-quality and strong welds, making it ideal for applications in the automotive and aerospace industries.

- Plastic: Laser welding machine is suitable for welding various types of plastics, including ABS, PVC, and PP. It provides high-quality and precise welds, making it ideal for applications in the medical device and electronics industries.

- Ceramic: Laser welding machine is suitable for welding various types of ceramics, including zirconia, alumina, and silicon nitride. It provides high-quality and precise welds, making it ideal for applications in the energy sector.

Application of Laser Welding Machine in Various Fields

Laser welding machine has a wide range of applications in various fields, including:

- Automotive Industry: Laser welding machine is used to weld car body parts, transmission systems, and exhaust systems.

- Aerospace Industry: Laser welding machine is used to weld aircraft components, engine parts, and missile components.

- Medical Device Manufacturing: Laser welding machine is used to weld medical devices, implants, and surgical instruments.

- Electronics Industry: Laser welding machine is used to weld electronic components, connectors, and sensors.

- Energy Sector: Laser welding machine is used to weld solar cells, fuel cells, and batteries.

Future Development Trends and Opportunities of Laser Welding Machine Products

The future development trends and opportunities of laser welding machine products are:

- Increased Automation: Laser welding machines are becoming more automated, which reduces labor costs and increases production efficiency.

- Improved Beam Quality: Laser welding machines are being developed with improved beam quality, which improves welding precision and quality.

- Application in New Fields: Laser welding machines are being applied in new fields, such as the food industry and the jewelry industry.

- Increased Demand: The demand for laser welding machines is expected to increase in the coming years, driven by the growth of the automotive, aerospace, and electronics industries.

How to Choose a Suitable Laser Welding Machine

Choosing a suitable laser welding machine can be analyzed from several aspects:

- Material Compatibility: Choose a laser welding machine that is compatible with the material you want to weld.

- Welding Type: Choose a laser welding machine that is suitable for the type of welding you want to perform, such as spot welding or seam welding.

- Power Requirements: Choose a laser welding machine that has the required power output for your welding needs.

- Automation Level: Choose a laser welding machine that has the required automation level for your production needs.

- Beam Quality: Choose a laser welding machine that has the required beam quality for your welding needs.

- Cooling System: Choose a laser welding machine that has a suitable cooling system to prevent overheating during the welding process.

Summary

Laser welding machine is a high-tech equipment that uses laser technology to weld metals. It has many performance characteristics that make it stand out in the welding industry. There are several types of laser welding machines available in the market, including CO2 laser welding machine, fiber laser welding machine, and YAG laser welding machine. Laser welding machines have a wide range of applications in various fields, including the automotive industry, aerospace industry, medical device manufacturing, electronics industry, and energy sector. The future development trends and opportunities of laser welding machine products include increased automation, improved beam quality, application in new fields, and increased demand. When choosing a suitable laser welding machine, it is important to consider material compatibility, welding type, power requirements, automation level, beam quality, and cooling system.

Disclaimer: All content on this page is from the Internet, and is only for reference for product selection. Our products are replacement parts, not original spare parts. We are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy.

Author: Dream