Your cart is currently empty!

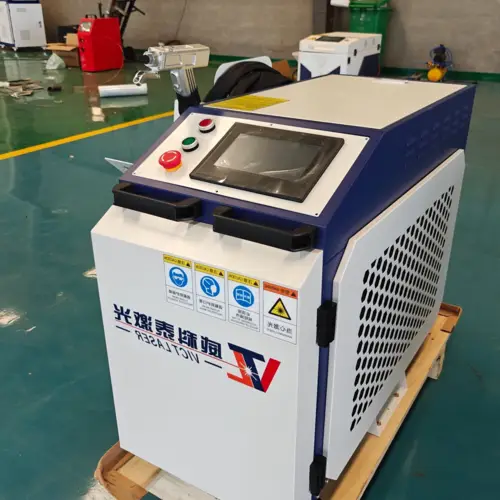

China Good quality 1.5kw Handheld Laser Welding Machine for Carbon Steel Stainless Steel Aluminium Copper air compressor parts

High-Quality Handheld Laser Welding Machine for Metalworking

Product Description

The HWF Series Portable Welding Machine is a powerful, 5-in-1 handheld fiber laser welding and cleaning machine. This machine is perfect for welding a variety of metals, including carbon steel, stainless steel, aluminum, and copper. It is especially suitable for welding air compressor parts.

This laser welding machine is designed to solve several common welding problems. For example, it can remove surface rust, paint, and oil dirt, which can interfere with welding. It can also clean raw materials without causing damage, which can be difficult to achieve with chemical cleaning or manual grinding. Additionally, this machine is cost-effective, as it combines several functions into one machine, saving you space and money.

Why Choose Us?

Our HWF Series Portable Welding Machine has several advantages:

- Easily Learning: Even if you have no welding experience, you can learn how to weld quickly and easily with this machine.

- Fast Switching: One machine with multiple functions and only change simple parts.

- Portable Welding: One machine can do all the welding work, saving space and cost.

- Maximum Security: Our machine is safer and more environmentally friendly than other welding methods.

Product Parameters

Here are the product parameters for the HWF-1500C:

| MODEL | HWF -1500C | |||||

| Laser type | Fiber | |||||

| Wavelength | 1080nm | |||||

| Power | 1500W | |||||

| Frequency | 20-5000Hz | |||||

| Output focal length | 150mm | |||||

| ScHangZhou range | Line 0-5mm@welding; Line 300mm@cleaning | |||||

| Depth of welding | max.5mm | |||||

| Cooling method | Water cooling | |||||

| Fiber length | 10M | |||||

| Port | 1 way gas | |||||

| Power consumption | ≤6KW | |||||

| Air pressure requirement | 4-6Bar(Select nitrogen,argon according to process requirements.) | |||||

| Electricity demand | 1500W @ AC220VAC 50/60Hz | |||||

FAQs

1. What is the HWF Series Portable Welding Machine?

The HWF Series Portable Welding Machine is a powerful, 5-in-1 handheld fiber laser welding and cleaning machine that is perfect for welding a variety of metals, including carbon steel, stainless steel, aluminum, and copper. It is especially suitable for welding air compressor parts.

2. What problems does the HWF Series Portable Welding Machine solve?

The HWF Series Portable Welding Machine can remove surface rust, paint, and oil dirt, which can interfere with welding. It can also clean raw materials without causing damage, which can be difficult to achieve with chemical cleaning or manual grinding. Additionally, this machine is cost-effective, as it combines several functions into one machine, saving you space and money.

3. Can I learn how to use the HWF Series Portable Welding Machine if I have no welding experience?

Yes, the HWF Series Portable Welding Machine is designed to be easily learned by anyone, even if they have no welding experience.

4. What are the advantages of the HWF Series Portable Welding Machine?

The HWF Series Portable Welding Machine has several advantages, including fast switching between functions, portability, and maximum security.

5. What are the product parameters for the HWF-1500C?

The product parameters for the HWF-1500C include laser type, wavelength, power, frequency, output focal length, Scan range, depth of welding, cooling method, fiber length, port, power consumption, air pressure requirement, and electricity demand.

Our company mainly supplies various industrial products, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We offer high-quality products, preferential prices, and thoughtful services. Customers are welcome to customize with drawings and samples.

Performance Characteristics of Laser Welding Machine

Laser welding machine is a high-tech equipment that uses laser technology to weld metals. It has many performance characteristics that make it stand out in the welding industry:

- Precise Welding: Laser welding machine uses a focused laser beam to create a precise and accurate weld, making it ideal for intricate welding jobs.

- High Speed: The laser welding machine has a high welding speed, which reduces the welding time and increases production efficiency.

- Non-Contact Welding: Laser welding machine uses a non-contact welding process, which reduces the risk of contamination and minimizes the damage to the material.

- Low Heat Input: Laser welding machine has a low heat input, which reduces the heat-affected zone and minimizes the distortion of the material.

- Wide Range of Material Compatibility: Laser welding machine can weld a wide range of materials, including metals, plastics, ceramics, and more.

Types and Characteristics of Laser Welding Machine

There are several types of laser welding machines available in the market, including:

- CO2 Laser Welding Machine: It is suitable for welding thick materials and has good welding depth.

- Fiber Laser Welding Machine: It is suitable for welding thin materials and has high welding speed.

- YAG Laser Welding Machine: It is suitable for welding small and precise parts.

The characteristics of laser welding machines vary depending on the type and model. However, some common characteristics include:

- High Welding Speed: Laser welding machines have a high welding speed, which reduces the welding time and increases production efficiency.

- High Precision: Laser welding machines have a high precision, which ensures accurate and consistent welding results.

- Non-Contact Welding: Laser welding machines use a non-contact welding process, which reduces the risk of contamination and minimizes the damage to the material.

- Wide Range of Material Compatibility: Laser welding machines can weld a wide range of materials, including metals, plastics, ceramics, and more.

Advantages of Laser Welding Machine Made of Different Materials

The advantages of laser welding machine made of different materials are:

- Metal: Laser welding machine is suitable for welding various types of metals, including stainless steel, aluminum, and titanium. It provides high-quality and strong welds, making it ideal for applications in the automotive and aerospace industries.

- Plastic: Laser welding machine is suitable for welding various types of plastics, including ABS, PVC, and PP. It provides high-quality and precise welds, making it ideal for applications in the medical device and electronics industries.

- Ceramic: Laser welding machine is suitable for welding various types of ceramics, including zirconia, alumina, and silicon nitride. It provides high-quality and precise welds, making it ideal for applications in the energy sector.

Application of Laser Welding Machine in Various Fields

Laser welding machine has a wide range of applications in various fields, including:

- Automotive Industry: Laser welding machine is used to weld car body parts, transmission systems, and exhaust systems.

- Aerospace Industry: Laser welding machine is used to weld aircraft components, engine parts, and missile components.

- Medical Device Manufacturing: Laser welding machine is used to weld medical devices, implants, and surgical instruments.

- Electronics Industry: Laser welding machine is used to weld electronic components, connectors, and sensors.

- Energy Sector: Laser welding machine is used to weld solar cells, fuel cells, and batteries.

Future Development Trends and Opportunities of Laser Welding Machine Products

The future development trends and opportunities of laser welding machine products are:

- Increased Automation: Laser welding machines are becoming more automated, which reduces labor costs and increases production efficiency.

- Improved Beam Quality: Laser welding machines are being developed with improved beam quality, which improves welding precision and quality.

- Application in New Fields: Laser welding machines are being applied in new fields, such as the food industry and the jewelry industry.

- Increased Demand: The demand for laser welding machines is expected to increase in the coming years, driven by the growth of the automotive, aerospace, and electronics industries.

How to Choose a Suitable Laser Welding Machine

Choosing a suitable laser welding machine can be analyzed from several aspects:

- Material Compatibility: Choose a laser welding machine that is compatible with the material you want to weld.

- Welding Type: Choose a laser welding machine that is suitable for the type of welding you want to perform, such as spot welding or seam welding.

- Power Requirements: Choose a laser welding machine that has the required power output for your welding needs.

- Automation Level: Choose a laser welding machine that has the required automation level for your production needs.

- Beam Quality: Choose a laser welding machine that has the required beam quality for your welding needs.

- Cooling System: Choose a laser welding machine that has a suitable cooling system to prevent overheating during the welding process.

Summary

Laser welding machine is a high-tech equipment that uses laser technology to weld metals. It has many performance characteristics that make it stand out in the welding industry. There are several types of laser welding machines available in the market, including CO2 laser welding machine, fiber laser welding machine, and YAG laser welding machine. Laser welding machines have a wide range of applications in various fields, including the automotive industry, aerospace industry, medical device manufacturing, electronics industry, and energy sector. The future development trends and opportunities of laser welding machine products include increased automation, improved beam quality, application in new fields, and increased demand. When choosing a suitable laser welding machine, it is important to consider material compatibility, welding type, power requirements, automation level, beam quality, and cooling system.

Disclaimer: All content on this page is from the Internet, and is only for reference for product selection. Our products are replacement parts, not original spare parts. We are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy.

Author: Dream